Fleet fuel efficiency is undoubtedly one of the key pillars of fleet management. It can dramatically impact your business’s overall performance and dictate your fleet’s growth potential.

After all, fuel costs are considered the most substantial expense for motor carriers per mile. Understanding this pivotal factor can help you achieve cost-effective operations.

Whether you manage a small delivery fleet or a large-scale transportation network, optimizing fuel efficiency can substantially impact your bottom line and environmental sustainability.

In the following sections, we’ll dive deep into fleet fuel efficiency, exploring what it is, why it’s important, and how you can improve it.

What is fuel efficiency and why is it important?

Before we can get into the details of how to improve fleet fuel efficiency, it’s essential to understand the term in the first place.

Fleet fuel efficiency or fuel economy shows what distance your fleet can cover using a specific quantity of fuel. It’s usually measured in miles per gallon (MPG) for vehicles that run on gasoline or diesel.

By calculating fleet fuel efficiency, you can gain insight into how efficiently a vehicle uses fuel to propel itself, with higher MPG indicating better fuel efficiency.

This metric is a paramount concern for fleet managers and drivers for several reasons:

- Cost savings – Better fuel efficiency translates into lower fuel expenses. This can significantly influence the operating costs of a fleet.

- Environmental impact – Decreasing fuel consumption not only saves money but also minimizes greenhouse gas emissions and reduces the fleet’s environmental footprint. It, therefore, contributes to a company’s sustainability goals and enhances its public image.

- Competitive advantage – Fuel-efficient fleets achieve a competitive edge by providing more cost-effective services to clients. In addition, governments and regulators often incentivize fuel-efficient practices through tax breaks and subsidies.

What affects a vehicle’s fleet fuel efficiency?

To understand how to improve fleet fuel economy, it’s essential to grasp the factors influencing a vehicle’s fuel efficiency.

Several variables come into play, influencing truck fleet fuel economy:

- Vehicle type – Different types of vehicles have varying levels of fuel efficiency. Compact cars tend to be more fuel-efficient than large trucks or buses.

- Driving conditions – Fuel efficiency can vary based on terrain, traffic conditions, and weather.

- Vehicle weight – Heavier vehicles generally consume more fuel, making payload management crucial for efficiency.

- Engine efficiency – The design and condition of the vehicle’s engine play a significant role in fuel efficiency.

- Aerodynamics – The shape and design of the vehicle affect its resistance to air, impacting fuel consumption.

How to calculate fleet fuel efficiency?

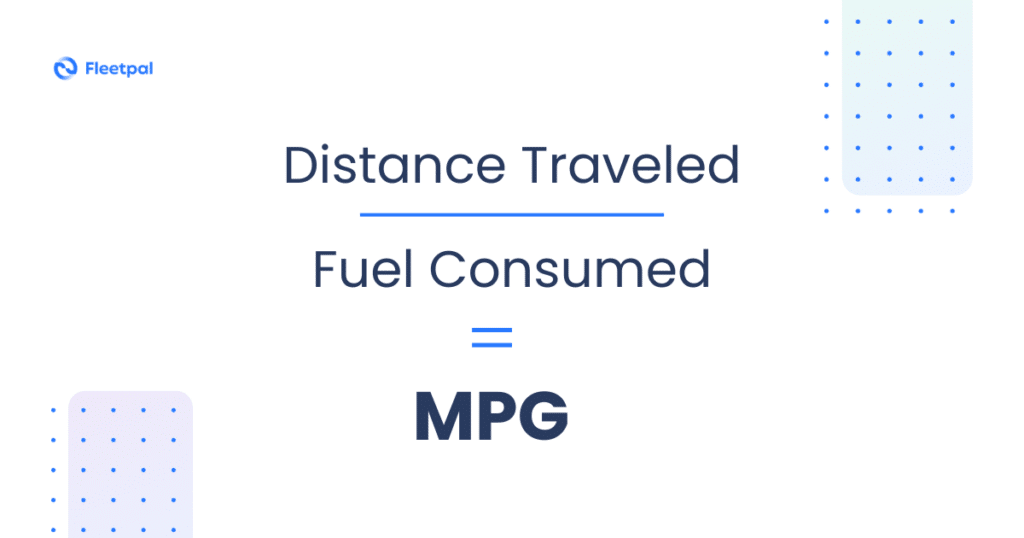

To calculate fleet fuel efficiency, you’ll need to gather information on the distance traveled and the fuel consumed.

The formula for calculating MPG is straightforward:

If you’re tracking fleet fuel efficiency manually, note how much fuel you’re putting into your vehicle and record your current odometer reading. When you next refuel, check the new odometer reading and record the change. In addition, note the amount of fuel used up.

Next, take away the original odometer reading from the second reading. As a result, you’ll get the distance your truck or other vehicle can cover using a specific amount of fuel.

Divide the distance by the quantity of fuel used by the vehicle. This will give you your fleet fuel efficiency or fuel economy.

The final step is to repeat this process for all vehicles in your fleet and calculate the average for the entire fleet.

Average fleet fuel economy

Understanding the average fuel economy of your fleet provides valuable insights into its performance.

But to be aware of how your vehicles are performing compared to others, you’ll need to be aware of the industry’s average fuel economy numbers.

According to ATRI survey respondents, the average fuel economy for truck tractors is 6.5 mpg. If your fuel economy is higher than this – great news! You’re achieving excellent fuel efficiency.

However, remember that this number will vary from company to company.

Why? Because numerous factors influence fuel economy:

- The vehicle’s age and condition

- Driver behavior

- Route specifics

- Payload size

Now, let’s take a look at some of the reasons why some fleets suffer from poor fuel economy.

What causes poor fuel economy?

What’s the meaning of poor fuel economy, and what causes it?

In short, poor fuel economy means that your vehicles consume more fuel to cover a specific distance.

This scenario can result from a cocktail of factors, increasing operational costs and environmental impact.

Some popular causes of poor fuel economy include:

- Inadequate vehicle maintenance – Neglecting preventive maintenance can result in engine inefficiencies, higher friction, and lower fuel economy.

- Excessive idling – Vehicles left idling for extended periods consume fuel without progressing, contributing to poor fuel economy.

- Inefficient routes – Routes that are more difficult to cover can lead to longer travel distances and increased fuel consumption.

- Payload mismanagement – Overloading vehicles can strain the engine and reduce fuel efficiency.

So, what can fleet managers do to prevent this?

How can fleet managers improve fleet fuel efficiency?

Luckily, there are plenty of fleet management fuel consumption best practices that you can implement to improve your fleet fuel economy.

Here are several strategies you can adopt as a fleet manager:

Keep up with preventive maintenance

Regular maintenance ensures that vehicles operate at their peak efficiency. And the best way to guarantee this is via preventive maintenance.

Well-maintained trucks are less prone to breakdowns and consume less fuel. For example, taking a predictive rather than a responsive approach to tire maintenance, oil change, and other components can help you avoid risks of decreased fuel efficiency.

Ideally, rely on fleet maintenance software that empowers you to tackle tiny issues before they become costly.

Minimize idling

As noted above, idling is one of the popular reasons for poor fuel economy.

The best way to reduce idling is through advanced telematics tools. These solutions offer insights into driver efficiency and vehicle performance. Based on data, you can identify how much fuel drivers are unnecessarily using due to idling.

Although idling is seldom intentional, it can lead to detrimental effects. The good news is that this problem can be eliminated via consistent coaching and training programs.

Opt for better routes

Fleet managers often assume that the shortest way to reach a destination is also the most fuel-efficient. This is a common misconception that can lead to expensive losses.

A journey packed with turns, curves, and uphill drives is bound to hurt your fuel consumption. Rather than choosing the routes that seem shortest, think about fuel efficiency.

The characteristics of an ideal route include:

- Highway dominance

- Flat terrains and downhill areas

- Fewer traffic jams

- Less idle time

Utilizing route optimization software can help you identify the shortest, fastest, and most fuel-efficient routes, reducing fuel consumption and travel time.

Use the recommended fuel grade

Using the recommended fuel grade for your vehicle can significantly improve its fuel efficiency.

Modern engines are designed to operate most efficiently with a specific fuel type. Using the manufacturer-recommended fuel grade ensures that the engine performs as it was created to. This means better combustion, smoother operation, and overall more efficient fuel usage.

Higher-grade fuels often have a higher octane rating, which helps prevent engine knocking. Engine knocking occurs when fuel combusts prematurely in the engine cylinders, leading to inefficient operation and potential engine damage. Using the correct fuel grade minimizes this risk, thereby maintaining engine efficiency.

In addition, when an engine runs on the appropriate fuel, it tends to experience less wear and tear. This is because the internal components are operating under optimal conditions. Over time, this can lead to a longer engine life and reduced maintenance costs.

Consider your vehicle’s parameters when organizing payloads

Another point we mentioned earlier is that heavier loads can be critical for fuel economy. The heavier the shipment, the more work the vehicle is forced to do to transport the goods.

Balancing payloads according to vehicle specifications helps prevent overloading, which can decrease fuel efficiency and cause premature wear and tear on the vehicle.

If you’re searching for a way to decrease payloads, several options exist.

First, you can ensure that all clutter is removed from the vehicle. This could mean cleaning out pallets, extra tires, unnecessary tools, and others. Although this won’t reduce your payload to a minimum, it will contribute to a lighter vehicle.

Second, you can think about making reductions to your vehicle’s length. For instance, if you’re operating with extremely long semi-trucks, think of ways to take away some of the length. In some cases, this could mean removing any sleeping or resting spaces.

Last but not least, make sure that goods are balanced appropriately across your vehicles. Don’t put all of the weight on a single truck to save money. In most cases, this will result in poor fuel economy.

Invest in technology

Incorporating fuel management or fleet maintenance technology can, without a doubt, positively affect your fleet’s fuel efficiency.

These solutions are designed to help you identify the areas causing your fuel economy to stumble. By pinpointing specific challenges, you can make informed decisions for improvements.

For example, telematics, GPS tracking, and fuel monitoring systems offer access to essential data for optimizing fleet operations and improving fuel efficiency in the long run. In addition, fleet maintenance software with Preventive Maintenance Intervals can help you keep your vehicles.

How can drivers help improve fuel efficiency?

Drivers also play a crucial role in fuel efficiency. After all, they’re responsible for operating the vehicles daily.

Educating and incentivizing drivers to adopt fuel-efficient driving habits can yield significant benefits.

Let’s explore some of the core ways in which those behind the wheel can make an impact.

Keep a consistent speed

Maintaining a consistent speed is one of the most important things for improving fleet fuel efficiency from a driver’s perspective.

Aggressive driving behavior and shifting speeds can force the vehicle to consume much more fuel than necessary.

Cruise control is an effective way to avoid this challenge. Educate your drivers to use cruise control and maintain a steady pace when on the go.

Be aware of speed limits

Believe it or not, driving at or below posted speed limits enhances safety and improves fuel efficiency.

Specific terrains require a certain driving behavior to ensure the lowest possible fuel consumption.

Encourage your drivers to drive according to the rules, as this can substantially impact your fuel economy.

Minimize idle time

Although reducing idle time requires a strategic approach from management, drivers will be responsible for executing the techniques.

For example, minimizing idle time by turning off the engine when parked or waiting can lead to substantial fuel savings.

Ensure that your drivers are aware of the practices that lead to idle time and enforce processes for eliminating them, where possible.

8 vital metrics for improving fleet fuel efficiency

We’ll also have to look at a few core metrics to fully answer how to improve fleet fuel efficiency.

To systematically improve fuel efficiency, it’s essential to monitor and analyze the following.

Fuel efficiency

Fuel efficiency is the primary indicator of fuel efficiency, measured in miles per gallon. In the previous sections, we explained in detail what this metric is and how to measure it.

Fuel consumption rate

The fuel consumption rate quantifies how much fuel a vehicle uses over a certain distance or time.

Unlike miles per gallon (MPG), which measures the distance a vehicle can travel per unit of fuel, fuel consumption rate focuses on the amount of fuel used, either in relation to distance or per hour of engine operation.

Fuel consumption estimated cost

Fuel consumption estimated cost is a valuable metric for calculating the anticipated expense associated with a vehicle’s fuel use over a certain distance or time.

This figure translates fuel efficiency into a concrete financial term, aiding in budgeting and financial planning.

To calculate this metric, multiply the volume of fuel a vehicle is expected to consume by the current price of that fuel.

For example, if a car uses 4 gallons of fuel to travel 100 miles and the gas price is $3 per gallon, the cost to travel those 100 miles would be $12.

Engine run time

Engine run time helps understand the usage and wear of an engine beyond just the distance traveled.

It offers a more nuanced view of engine wear, especially when idling or stationary use is expected.

This metric is instrumental in planning maintenance, calculating costs, and ensuring engines’ longevity and safe operation across various industries.

Idle time

Throughout this article, we’ve mentioned idle time on several occasions.

Engine idle time measures the duration for which a vehicle’s engine remains running while the vehicle is stationary.

This metric is crucial for understanding the environmental and economic impact of vehicle use.

Idle time percentage

On the other hand, engine idle time percentage quantifies the proportion of total engine operation time spent idling.

It’s an insightful measure that sheds light on vehicle usage patterns, especially when a vehicle spends significant time stationary with the engine running.

The idle time percentage is calculated by dividing the time the engine spends idling by the total engine running time, then multiplying by 100 to express it as a percentage.

This calculation provides a clear picture of how much of the engine’s operation is non-productive in terms of movement.

Tire pressure

Tire pressure percentage describes the level of inflation of a vehicle’s tires in relation to the recommended optimal tire pressure. This metric is expressed as a percentage and is important for vehicle safety, fuel efficiency, and the tires’ longevity.

Most importantly, it’s essential for understanding fleet fuel efficiency.

The concept of tire pressure percentage is straightforward. It compares the current tire pressure with the manufacturer’s recommended pressure.

Aerodynamic drag

Aerodynamic drag is critical in understanding how air resistance impacts a vehicle’s efficiency and performance.

It’s essentially a force that opposes the motion of an object through the air. For vehicles, this drag is a significant factor in determining how much energy is required to maintain a certain speed.

Reducing aerodynamic drag is crucial as a lower drag means better fuel efficiency since the engine doesn’t have to work as hard to overcome resistance.

Conclusion

In conclusion, fleet fuel efficiency is critical to managing a cost-effective and sustainable fleet operation. By understanding the factors influencing fuel efficiency, implementing best practices for fleet managers and drivers, and closely monitoring key metrics, you can significantly reduce costs, lower your environmental impact, and gain a competitive edge in your industry.

Don’t forget that you can rely on Fleetpal for a reliable fleet maintenance solution that can help you optimize fleet fuel efficiency.

Ready to find out more? Schedule a free online demo with one of our representatives, and we’ll show you how!